A trapdoor box for dropping payloads remotely.

Dropper Box with Radio Frequency Control.

I created this box with a trap door so I could use it with my students during physics lessons. The controller box and dropper box communicate with each other using radio frequency transceivers connected to Arduino Unos. The dopper box is made of laser cut plywood and 3D printed components designed in Autodesk's Fusion 360. The controller box is made of laser cut acrylic.

Electronics of the dropper box. Arduino, RF module, 12V battery pack, 12V solenoid, and custom 3D printed parts can be seen.

Electronics of the dropper box. Arduino, RF module, 12V battery pack, 12V solenoid, and custom 3D printed parts can be seen.

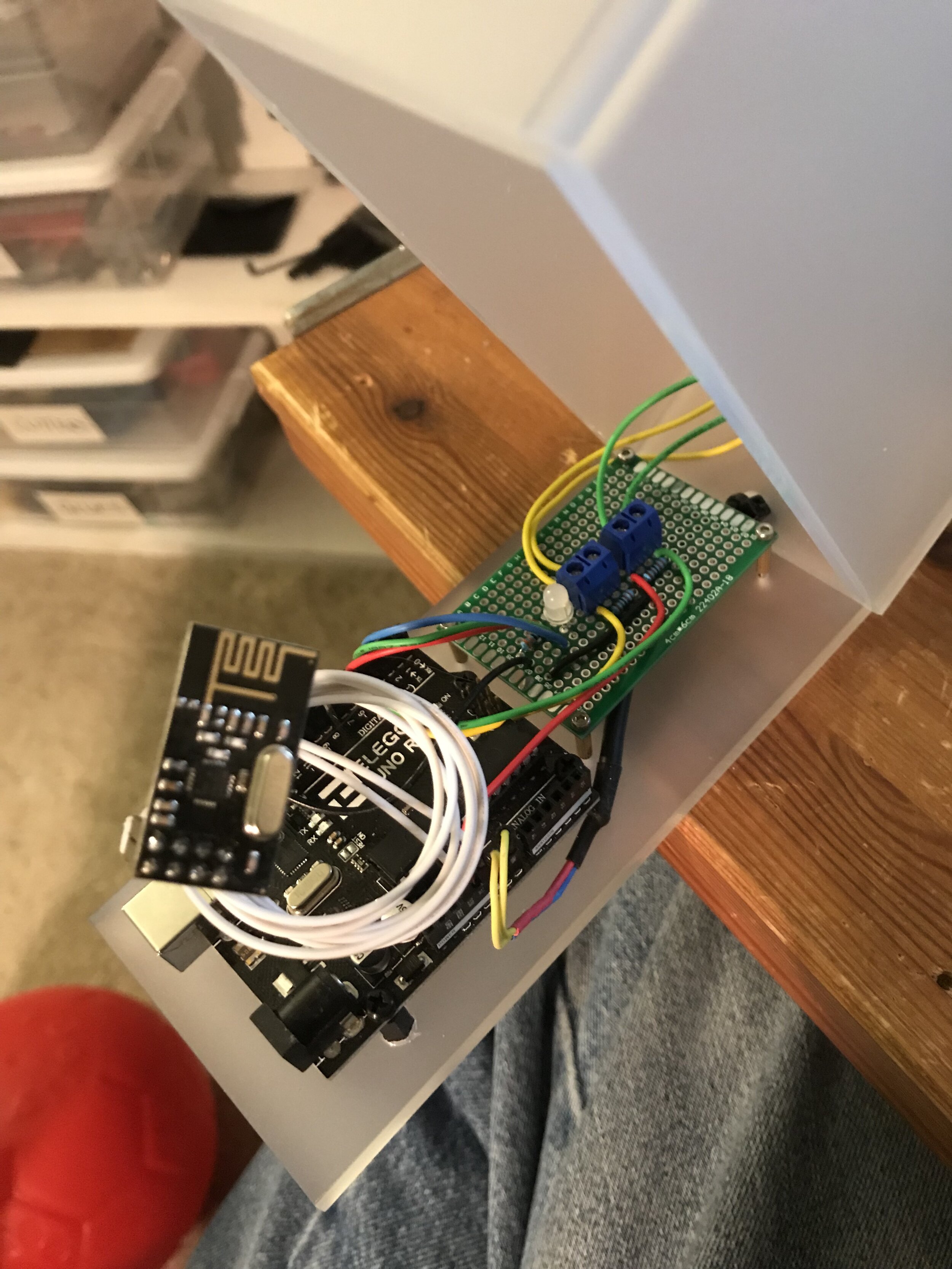

Internal circuit of the controller box. Arduino Uno, RF module, RGB LED, and button connection points are mounted on laser cut acrylic base.

Exterior of controller box, made from laser cut acrylic. Normally open execute button and keyed safety switch are seen.

Controller box made of laser cut acrylic when it is powered and in an unarmed state. When the key is turned the Arduino turns the RGB LED red and will accept input from the push button. This will send a radio signal to the RF module on the dropper box.

Another interior view of the controller box, with the Arduino Uno, RF module, RGB LED, and connection points for the buttons visible. Laser cut acrylic box has been opened.